Stomach satisfied, I unloaded the car and changed into my overalls before wandering down the meandering footpath that comes out in the yard. Having left before the engines went to bed yesterday, I was surprised to see them stabled on and around 'middle road'. The immaculate 4-6-0s were simmering away to themselves quietly in the company of the smaller Pannier Tank No9600...

Then came the offer to go out with 9600 for the day and this was of course gratefully accepted. Driver Dave was already there and was checking the engine over. She was still holding her own on yesterdays heat, with 40psi remaining on the clock, and thus wouldn't require much coaxing to bring her back to the boil. The fire had been made up in warming fire fashion at the back of the box and, following an energetic swinging of the dart from Dave, it began to smoulder away on the grate. An inspection beneath the 0-6-0 then revealed that the ashpan was rammed full and so a gentle hiss backwards through the running part of the shed was necessary to reach the nearest outside pit. Dave removed the pan guards (necessary for Network Rail operation) and I then went underneath the now crackling Pannier in order to reach the pan of ash.

Ashing out is one of those activities that you wish everyone that romanticises about steam could do for you. The hot, steaming bulk of several tons of iron and steel is doing its best to burn you while you work away with a cumbersome implement, wet at the boots and covered in dust, clattering and banging for all you're worth. The steam brake cylinder is often dripping neatly down your neck, the hose pipe is filling the pit in a very much hole in the canoe fashion and its only a matter of time before your luck runs out and you get the dreaded "wet sock experience". (That is enough to strike misery into you for the rest of your day!). Luckily, this morning I managed to escape the sock soaking and 9600 was soon happily nursing a good fire, in part thanks to a clean ashpan. The blue sky that now hovered above the engine provided the very encouraging shot below...

Ashpan emptied, the engine dropped back through the shed to join 4965 and 5043 once again. Dave was going around the engine with the oil can, whilst I gave the rods a rub over with the cloths. Just after 9am, we decided to start the shunting procedures that would get the days operations underway. So, it was up into the cab...

9600 was built at Swindon in 1945 as one of the numerous 5700-type varients of the Pannier Tanks. Panniers were very popular on the Great Western, providing Class 4 motive power with tanks that allowed access to the valve gear and cranks beneath the boiler. This varient has a slightly taller cab with large square windows, as opposed to the earlier types with the usual cab height and round spectacles. Engines like 9600 were common on freight moves, empty coaching stock workings and local passenger services across the network. She was withdrawn from Neath Shed in 1965 and a reprieve from the scrapyard then came in the unlikely form of the NCB. The Pannier ended up at Merthyr Vale Colliery, where she worked until withdrawal in 1973. I've been lucky enough to have had a couple of scanned images sent in of her during her time there...

|

| "9600 in NCB Days. New Years Day 1969" (Pic - H.Llewelyn) |

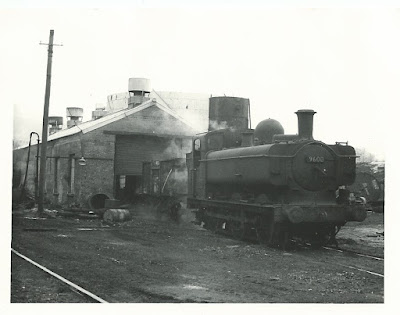

I think that the shot below, taken in 1971, shows the locomotive's coal board condition. I believe that the LH numberplate was missing by then. The preservation turnaround is beautiful. Tyseley always keep their engines well, but No9600 is still like a new un'...

|

| "9600 at Merthyr Vale - New Years Day 1971" (Pic - H.Llewelyn) |

Whilst 9600 sat around the turntable, 4965 & 5043 took turns trundling on and off for photographs. Meanwhile, behind us, 52' was chugging up and down at regular intervals. It was then time, after a cuppa', to do a spot of Pannier anatomy searching. As we were now over another pit, I headed off underneath (feeder in hand) to attempt to get the crank big ends and the four eccentrics. Pannier's employ inside Stephenson's valve gear, connecting 17.5" cylinders to the wheels under a 200psi boiler. I managed to get the eccentrics from underneath but the position of the big ends required a little more contortionism. You have to sit side-saddle on the running plate and squeeze your head in, arms first, through the gap over the splasher behind the toolbox. There is only one way in, and thus only one way out. The chassis is very much the heart of the Pannier...

After a pleasant morning sat around the turntable, the fire was made up slightly to keep the engine on the boil. The 1pm Cavalcade, featuring the two 4-6-0s, would require us to swap duties with 52' whilst the shuttle set was stabled in the 'middle road'. After a spot of shunting under the shattering barks of two Western thoroughbred's storming up and down the demo line, 9600 was in place...

|

| "GWR Pannier Tank No9600, In BR Mixed Traffic Livery" |

Once the two big engines had done their bit, they reversed back through the engine shed. The dolly we had been waiting for duly tilted to clear and 9600 blew up the brake before reversing out onto the demo line. The engine then began the afternoon procession of steaming back and forth up the yard. One trip for the passenger means two trips each way up and down the yard...

|

| "The Road Ahead On Another Passenger Shuttle" |

Having halted at the barrow crossing on your way back down, you whistle up and set out on your second working up the yard, propelling the train...

9600 is pictured at Tyseley Warwick Road platform, awaiting another shuttle outing...

Dave kindly let me take 9600 for a couple of trips up & down the yard on the shuttle and what a pleasant engine this is. "It just does what you want", to quote an engineman friend. Due to the engine's ex-NCB condition at the beginning of restoration, a very thorough and exacting rebuild was required to get her back to main line running condition and you can see and feel this through every part of the machine. The regulator is like new, the reverser has zero play, the voice at the chimney is neat and square and the occasionally troublesome (on some engines) GWR combi-brake actually works perfectly well. Its a really lovely job and all credit to the lads at Tyseley who created such a fine machine. She really is a pleasure to drive and to be on in general. That's another one for the 'driven' list!

As the day wore on, the ash was building up in the fire, so much so that we stopped making it up with fresh coal and just rooted through it with the dart after each trip up the yard. Pressure was maintained at 180-ish and so the effects of the clogged grate weren't particularly evident. You can see the ash build up clearly, deadening the fire at the centre but burning bright at the edges where the air can reach up via the plate-work. Strange stuff...

Later, 52' shunt released 9600 which I then took over onto '2 Road' for stabling before going into the shed. 52' then rejoined her slightly younger sister, along with the pretty little Peckett No1. By now the weather had turned from cloudy to drizzly and conditions were set to worsen during the evening...

|

| "Panniers At Rest" |